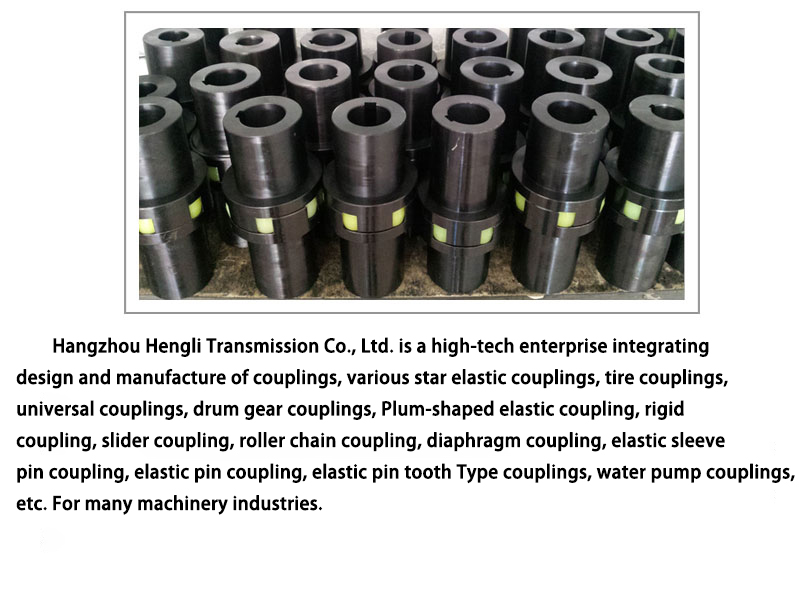

Product Series

![]()

-

Coupling diaphragm

-

Diaphragm coupling

-

Drum gear coupling

-

Tyre coupling

-

Plum elastic coupling

-

Star flexible coupling

-

Elastic pin coupling

-

Elastic sleeve pin coupling

-

Elastic pin gear coupling

-

Serpentine spring coupling

-

Roller chain coupling

-

Clamping coupling

-

Flange coupling

-

Slider coupling

-

H-type flexible coupling

-

Coupling accessories

Company News

MORE

GICL type-drum gear coupling

GICL type-drum gear coupling product description:

Drum gear couplingIt belongs to a rigid-flexible coupling. The gear coupling is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Drum gear couplings are allowed. Larger angular displacement (compared to straight tooth coupling) can improve the contact conditions of the teeth, increase the torque transmission capacity, and prolong the service life.The contact state along the tooth width when there is angular displacement.It has the ability to compensate for axis deviation in radial, axial and angular directions. It has the advantages of compact structure, small turning radius, large carrying capacity, high transmission efficiency, low noise and long maintenance cycle. It is especially suitable for low speed and heavy load conditions, such Metallurgy, mining, lifting and transportation industries, and also suitable for shafting transmission of various machinery such as petroleum, chemical industry, general machinery and so on.

When the gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the internal and external teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption. Therefore, the gear coupling must have a good and Work in a sealed state.Gear couplings have small radial dimensions and large load-bearing capacity. They are often used in shafting transmissions under low-speed and heavy-duty conditions. High-precision and dynamically balanced gear couplings can be used for high-speed transmissions, such as gas turbine shafting. transmission.Since the angular compensation of drum gear couplings is greater than that of spur gear couplings, drum gear couplings are widely used. Straight gear couplings are obsolete products and should not be used as much as possible.

Type I-The sealed end is a separate type, with a large tooth spacing, allowing a large radial displacement, and can be connected with Y, JXNUMX, and ZXNUMX shaft extensions.

Type Ⅱ-The sealing end is integral, with small tooth spacing, relatively small radial displacement, compact structure, small moment of inertia, and can be connected with Y and JXNUMX shaft extensions.

Main features (compared with straight gear couplings, it has the following features):

1. Strong carrying capacity.Under the same outer diameter of the inner gear sleeve and the outer diameter of the coupling, the carrying capacity of the drum gear coupling is 15-20% higher than that of the straight gear coupling on average.

2. Large angular displacement compensation.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1o, and the allowable angular displacement of the drum gear coupling is 1o30', an increase of 50%.Under the same modulus, number of teeth, and tooth width, the allowable angular displacement of the drum tooth is larger than that of the straight tooth.

3. The drum-shaped tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of squeezing the edge of the straight tooth and stress concentration under the condition of angular displacement, and at the same time improves the friction and wear of the tooth surface, and reduces the noise. , Long maintenance cycle.

4. The tooth end of the outer gear sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer teeth very convenient.

5. High transmission efficiency.

Based on the above characteristics, at present, drum-shaped teeth have generally been substituted for straight-tooth couplings.

| model | Nominal torque Tn(N·m) | Allowable speed [n] (r/min) | Diameter of shaft hole d1, d2, dz | Length of shaft hole | D | D1 | D2 | B | A | C | C1 | C2 | e | Moment of inertia (kg·m2) | Weight(kg) | |

| Y | Z1,J | |||||||||||||||

| L | ||||||||||||||||

| GICL1 | 630 | 4000 | 16 18 19 | 42 | - | 125 | 95 | 60 | 115 | 75 | 20 | - | - | 30 | 0.009 | 5.9 |

| 20 22 24 | 52 | 38 | 10 | - | 24 | |||||||||||

| 25 28 | 62 | 44 | 2.5 | - | 19 | |||||||||||

| 30 32 35 38 | 82 | 60 | 15 | 22 | ||||||||||||

| GICL2 | 1120 | 4000 | 25 28 | 62 | 44 | 144 | 120 | 75 | 135 | 88 | 10.5 | - | 29 | 30 | 0.02 | 9.7 |

| 30 32 35 38 | 82 | 60 | 2.5 | 12.5 | 30 | |||||||||||

| 40 42 45 48 | 112 | 84 | 13.5 | 28 | ||||||||||||

| GICL3 | 2240 | 4000 | 30 32 35 38 | 82 | 60 | 174 | 140 | 95 | 155 | 106 | 3 | 24.5 | 25 | 30 | 0.047 | 17.2 |

| 40 42 45 48 50 55 56 | 112 | 84 | 17 | 28 | ||||||||||||

| 60 | 142 | 107 | 35 | |||||||||||||

| GICL4 | 3550 | 3600 | 32 35 38 | 82 | 60 | 196 | 165 | 115 | 178 | 125 | 14 | 37 | 32 | 30 | 0.091 | 24.9 |

| 40 42 45 48 50 55 56 | 112 | 84 | 3 | 17 | 28 | |||||||||||

| 60 63 65 70 | 142 | 107 | 35 | |||||||||||||

| GICL5 | 5000 | 3300 | 40 42 45 48 50 55 56 | 112 | 84 | 224 | 183 | 130 | 198 | 142 | 3 | 25 | 28 | 30 | 0.167 | 38 |

| 60 63 65 70 71 75 | 142 | 107 | 20 | 35 | ||||||||||||

| 80 | 172 | 132 | 22 | 43 | ||||||||||||

| GICL6 | 7100 | 3000 | 48 50 55 56 | 112 | 84 | 241 | 200 | 145 | 218 | 160 | 6 | 35 | 35 | 30 | 0.267 | 48.2 |

| 60 63 65 70 71 75 | 142 | 107 | 4 | 20 | 35 | |||||||||||

| 80 85 90 | 172 | 132 | 22 | 43 | ||||||||||||

| GICL7 | 10000 | 2680 | 60 63 65 70 71 75 | 142 | 107 | 260 | 230 | 160 | 244 | 180 | 4 | 35 | 35 | 30 | 0.453 | 68.9 |

| 80 85 90 95 | 172 | 132 | 22 | 43 | ||||||||||||

| 100 | 212 | 167 | 48 | |||||||||||||

| GICL8 | 14000 | 2500 | 65 70 71 75 | 142 | 107 | 282 | 245 | 175 | 264 | 193 | 5 | 35 | 35 | 30 | 0.646 | 83.3 |

| 80 85 90 95 | 172 | 132 | 22 | 43 | ||||||||||||

| 100 110 | 212 | 167 | 48 | |||||||||||||

| GICL9 | 18000 | 2350 | 70 71 75 | 142 | 107 | 314 | 270 | 200 | 284 | 208 | 10 | 45 | 45 | 30 | 1.036 | 110 |

| 80 85 90 95 | 172 | 132 | 22 | 43 | ||||||||||||

| 100 110 120 125 | 212 | 167 | 5 | 49 | ||||||||||||

| GICL10 | 31500 | 2150 | 80 85 90 95 | 172 | 132 | 346 | 300 | 220 | 330 | 249 | 5 | 43 | 43 | 30 | 1.88 | 157 |

| 100 110 120 125 | 212 | 167 | 22 | 49 | ||||||||||||

| 130 140 | 252 | 202 | 29 | 54 | ||||||||||||

| GICL11 | 40000 | 1880 | 100 110 120 125 | 212 | 167 | 380 | 330 | 260 | 360 | 40 | 6 | 29 | 49 | 40 | 3.28 | 217 |

| 130 140 150 | 252 | 202 | 54 | |||||||||||||

| 160 | 302 | 242 | 64 | |||||||||||||

| GICL12 | 56000 | 1680 | 120 125 | 212 | 167 | 442 | 380 | 290 | 416 | 313 | 6 | 57 | 57 | 40 | 5.08 | 305 |

| 130 140 150 | 252 | 202 | 29 | 55 | ||||||||||||

| 160 170 180 | 203 | 242 | 68 | |||||||||||||

| GICL13 | 80000 | 1530 | 140 150 | 252 | 202 | 482 | 420 | 320 | 476 | 364 | 7 | 54 | 57 | 40 | 10.06 | 419 |

| 160 170 180 | 302 | 242 | 32 | 70 | ||||||||||||

| 190 200 | 352 | 282 | 80 | |||||||||||||

| GICL14 | 112000 | 1300 | 160 170 180 | 302 | 242 | 520 | 465 | 360 | 532 | 415 | 8 | 42 | 70 | 40 | 16.774 | 594 |

| 190 200 220 | 352 | 282 | 32 | 80 | ||||||||||||

| GICL15 | 160000 | 1180 | 190 200 220 | 352 | 282 | 580 | 510 | 400 | 556 | 429 | 10 | 34 | 80 | 40 | 26.55 | 783 |

| 140 250 | 38 | - | ||||||||||||||

| GICL16 | 250000 | 1000 | 200 220 | 352 | 282 | 680 | 595 | 465 | 640 | 501 | 10 | 58 | 80 | 50 | 52.22 | 1131 |

| 240 250 260 | 410 | 330 | 38 | - | ||||||||||||

| 280 | 470 | 380 | 38 | |||||||||||||

| GICL17 | 280000 | 980 | 220 | 352 | 282 | 720 | 645 | 495 | 672 | 512 | 10 | 74 | 80 | 50 | 69 | 1305 |

| 240 250 260 | 410 | 330 | 39 | - | ||||||||||||

| 280 330 | 470 | 380 | ||||||||||||||

| GICL18 | 355000 | 900 | 240 250 260 | 410 | 330 | 775 | 675 | 520 | 702 | 524 | 10 | 46 | - | 50 | 96.19 | 1626 |

| 280 300 320 | 470 | 380 | 41 | |||||||||||||

| GICL19 | 450000 | 830 | 260 | 410 | 330 | 815 | 715 | 560 | 744 | 560 | 10 | 57 | - | 50 | 115.6 | 1773 |

| 280 300 320 | 470 | 380 | 41 | |||||||||||||

| 340 | 550 | 450 | ||||||||||||||

| GICL20 | 500000 | 790 | 280 300 320 | 470 | 380 | 855 | 755 | 585 | 786 | 595 | 13 | 44 | - | 50 | 167.41 | 2263 |

| 340 360 | 550 | 450 | ||||||||||||||

| GICL21 | 630000 | 750 | 300 320 | 470 | 380 | 915 | 795 | 620 | 808 | 611 | 13 | 59 | - | 50 | 215.7 | 2593 |