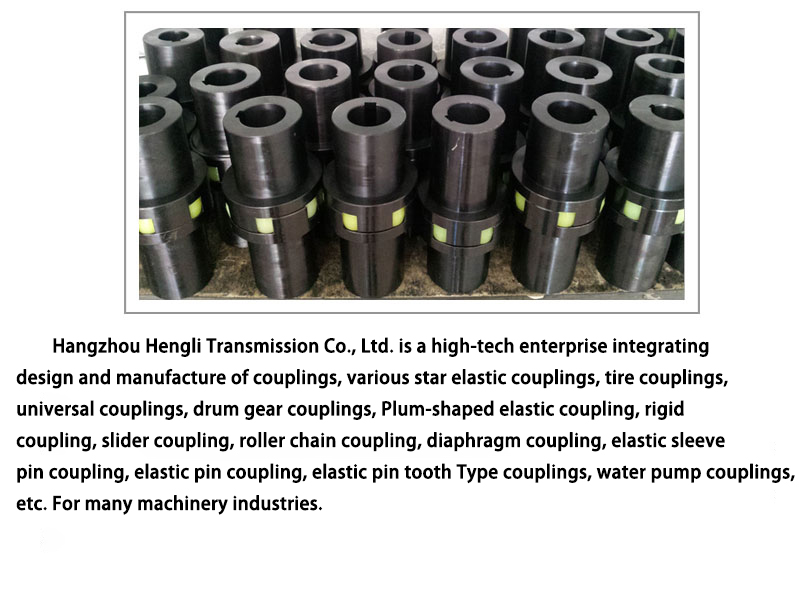

Product Series

![]()

-

Coupling diaphragm

-

Diaphragm coupling

-

Drum gear coupling

-

Tyre coupling

-

Plum elastic coupling

-

Star flexible coupling

-

Elastic pin coupling

-

Elastic sleeve pin coupling

-

Elastic pin gear coupling

-

Serpentine spring coupling

-

Roller chain coupling

-

Clamping coupling

-

Flange coupling

-

Slider coupling

-

H-type flexible coupling

-

Coupling accessories

Company News

MORE

4-hole coupling diaphragm

This feature of 4-hole coupling diaphragm is a bit like a ripple tube coupling, and the form of torque transmission by the actual pull coupling is the same.The diaphragm itself is very thin, because it is difficult to wind when the displacement mount occurs, so it can accept up to 1.5 degrees of deflection, and simultaneously produces a lower bearing load in the servo system.The diaphragm coupling is long used in the servo system. The diaphragm has good torque rigidity, but it is slightly inferior to the ripple tube coupling.On the other hand, the diaphragm coupling is good, if it is misused in operation or is not accurately assembled, it will be difficult to destroy.Because the guarantee bias is extremely redundant within the acceptance range of the general operation of the coupling.Choosing the right coupling is the key step to make good use of the coupling. You have to think about what type of coupling to choose during the customization phase.

The 4-hole coupling diaphragm consists of at most one diaphragm and two shaft sleeves.The coupling diaphragm is fastened to the shaft sleeve with a pin and will never loosen or cause backlash between the diaphragm and the shaft sleeve.Some manufacturers need two diaphragms, and some need three diaphragms, with one or two rigid parts, and the two sides are connected to the shaft sleeve.The difference between single-diaphragm coupling and double-diaphragm coupling is to solve the different types of deflection force. Because of its requirement that the diaphragm can be simply meandering, because the single-diaphragm coupling is not compliant fair.The dual-diaphragm coupling can simultaneously bend in different positions to make up for fairness.

When the diaphragm coupling is in high-speed operation or repeated forward and reverse rotation, the diaphragm group is subjected to alternating stress, which is prone to fatigue damage.Therefore, we will find that the service life of the diaphragm coupling is not long, and it is frequently damaged, and the diaphragm set needs to be replaced.It can be seen from the principle analysis of the actual damaged diaphragm group and diaphragm coupling that the damage of the diaphragm assembly mainly occurs near the hinge point of the diaphragm group.This is because when the alignment problem is not solved between the power machine and the working machine, there are angular deviations and axial deviations, and the diaphragm group in the diaphragm coupling that connects the power machine and the working machine will generate additional stress.

Shandong 4-hole coupling diaphragm Guangdong 4-hole coupling diaphragm