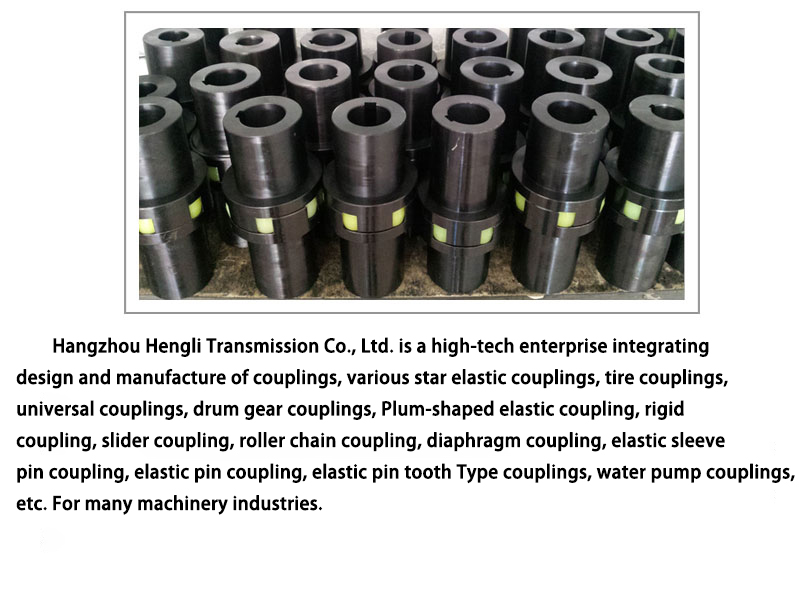

Product Series

![]()

-

Coupling diaphragm

-

Diaphragm coupling

-

Drum gear coupling

-

Tyre coupling

-

Plum elastic coupling

-

Star flexible coupling

-

Elastic pin coupling

-

Elastic sleeve pin coupling

-

Elastic pin gear coupling

-

Serpentine spring coupling

-

Roller chain coupling

-

Clamping coupling

-

Flange coupling

-

Slider coupling

-

H-type flexible coupling

-

Coupling accessories

Company News

MORE

Hexagonal diaphragm

The hexagonal diaphragm is the key element of the diaphragm flexible coupling. Due to the offset between the axes, the transmission of torque, and the bearing of centrifugal force, the diaphragm is in a complex state of stress during operation.The diaphragm is used as an elastic element. The bolts in the two adjacent holes on the diaphragm are connected to the convex edges of the shafts at both ends and the middle shaft respectively, that is, the bolts are arranged in opposite directions, resulting in relative displacement between them through the flexibility of the diaphragm. .When it is determined that the position of a hole is fixed, the normal force caused by the pre-deformation at the two adjacent holes can also be a fixed constraint for the third hole which is separated by one hole.Figure 4 illustrates the effect of this restraint and load.

Installation of hexagonal diaphragm:

1. Appropriate protective measures shall be taken at each site where personal and equipment accidents may be caused by the operating diaphragm coupling.The coupling diaphragm is composed of several groups of diaphragms that are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is made up of several pieces. The diaphragms are divided into connecting rod type and different shape of the whole piece type.

2. In order to prevent the fretting wear of the diaphragm during high-speed operation, causing microcracks and damage to the bolt holes of the diaphragm, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the surface of the diaphragm can be coated with anti-friction层处理。 Layer processing.

3. Before installation, clean the end faces of the two shafts and check the fit of the key grooves on the end faces. After installation, run a shift normally and check all screws. If found to be loose, tighten them. Repeat this for several shifts to ensure that they will not loosen.

4. During work and operation, check whether the diaphragm coupling is abnormal. If any abnormality occurs, perform maintenance.