Product Description

3/4″ COUPLING FITTING 3/4 INCH BLACK MALLEABLE CAST IRON PIPE for industrial pipe furniture

Malleable cast iron pipe and pipe fittings

Feature: Easy to assembly, anti-rust treatment.high strength, good toughness. DIY and meet various needs of customers, colorful painting, smooth surface, perfectly matched thread, precise dimensions, easy to install.

Color : Black,galvanized,natural,brass..or customized color as client’s request.

Technology: electrophoresis, electrophoresis and hot-dip, spraying plastics.

Size: 1/2″(DN15)-2″(DN50)

Thread: BSP/NPT,perfect and better to connect.

Usage: For DIY Furniture Decor – Vintage Pipe Shelf Brackets/Paper Holder/Coat Rack/more DIY furniture as your design drawing.

Material: Malleable cast iron

Type: Beaded end, banded end, plain end.

Related products: Floor flange, tee, cross, 90/45 deg elbow, M/F elbow, Mi side outlet

tee/cross, coupling, socket, reducer, cap, plug, pipe/tube, hand valve, taps, nipple.

Product picture

Application:

Packaging Details

General Packing:

1) Wrapping by plastic 1 by one, cartons with Pallets/wooden cases

2) Wrapping by plastic 1 by one, litter box, master cartons with pallets/wooden case

Customized packing:

3) Amazon packing standard:

Single plastic Bag per piece with barcode,

Pre-cartons,or 10pcs per Plastic bag with Label & barcode

4)The customized packing as client’s request is acceptable.

About Us

ZheJiang HangHong trading Co., LTD is a leading supplier and certified professional company dealing with below malleable cast iron pipe and pipe fittings and key clamp pipe fitting with different sizes under kinds of standards for 10 years.

-Linepipe, pipes, customized length pipe/tube

-Elbows:90 degree elbow and 45-degree elbow, F&M elbow.

-Flanges:3 holes floor flange and 4 holes floor flange

-Tee, Cross tee, Y tee, outlet tee

-Caps

-Other Pipe fittings

Malleable cast iron floor flange pipe fittings are our advantage for kind of products. We got more good feedback because of our competitive price, good quality, punctual shipment and excellent service. our products are widely exported to all over the world and enjoy good reputation.

“Only imperfect products, no picky customers”, we have strict and compete production line and testing equipment for keeping the products quality as the international standard. brand and reputation can prove it.

The clients will get when place order from us?

1)Competitive price, excellent service.

2)They can get the goods they really want.

3)Good shopping experience.

4)Fast reply not only before placing an order but also after getting the goods.

5)A friend like me and can supply the goods to you anytime when you need in the future.

FAQ:

1, Can you supply the free sample?

Yes, we can supply the free sample, but you need to pay the shipping cost.

2, What is the freight cost calculated based on?

The freight cost is based on the total weight, the heavier the weight, the more cost-effective the average freight.

3. What’s the MOQ?

Please don’t worry about the MOQ, we can produce the quantity according to your requirement.

4. What is the packing method for the products?

Firstly, we pack the fittings 1 by 1 use plastic film, then put into cartons, wooden cases or pallet

5. How I can pay for you?

T/T, Western Union, L/C

Why Choose US:

-Sufficient Forging, Heating, Machining Equipment

-In-house inspection instruments for strict quality controlling

-Competitive price & High-quality assurance

-Fast, effective and efficient after-sale services 24/7

-25 years experience professinonals on communications

-Fast delivery within 7-15 days

-100% inspection for all the products

-MOQ:1PCS

-Sample is acceptable and free /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any Safety Considerations or Guidelines Related to the Installation of Industrial Couplings?

Yes, the installation of industrial couplings requires careful attention to safety considerations and adherence to specific guidelines to ensure the coupling functions correctly and safely. Improper installation can lead to coupling failures, equipment damage, and potential hazards for personnel. Here are some essential safety considerations and guidelines related to the installation of industrial couplings:

- Follow Manufacturer Instructions: Always follow the manufacturer’s installation instructions and guidelines provided with the coupling. Manufacturers have specific recommendations for proper installation, which may vary depending on the coupling type and model.

- Use Proper Tools and Equipment: Use the appropriate tools and equipment for the installation process. Ensure that torque wrenches and other tools are properly calibrated to achieve the correct bolt torque and avoid over-tightening or under-tightening.

- Verify Shaft Alignment: Before installing the coupling, verify the alignment of the connected shafts. Proper shaft alignment is crucial to prevent premature wear, vibration, and misalignment-related issues during operation.

- Ensure Clean Surfaces: Clean and inspect the shaft ends and coupling bore to remove any dirt, debris, or old lubricants. Clean surfaces ensure proper contact and reduce the risk of contamination inside the coupling.

- Check Coupling Fit: Ensure that the coupling fits properly on the shafts and that there is sufficient clearance between the coupling and surrounding components. Avoid interference that could lead to mechanical binding during operation.

- Verify Keyway and Key Fit: If the coupling uses a keyway and key for torque transmission, verify that the key fits securely and accurately in the keyway without any play or gaps.

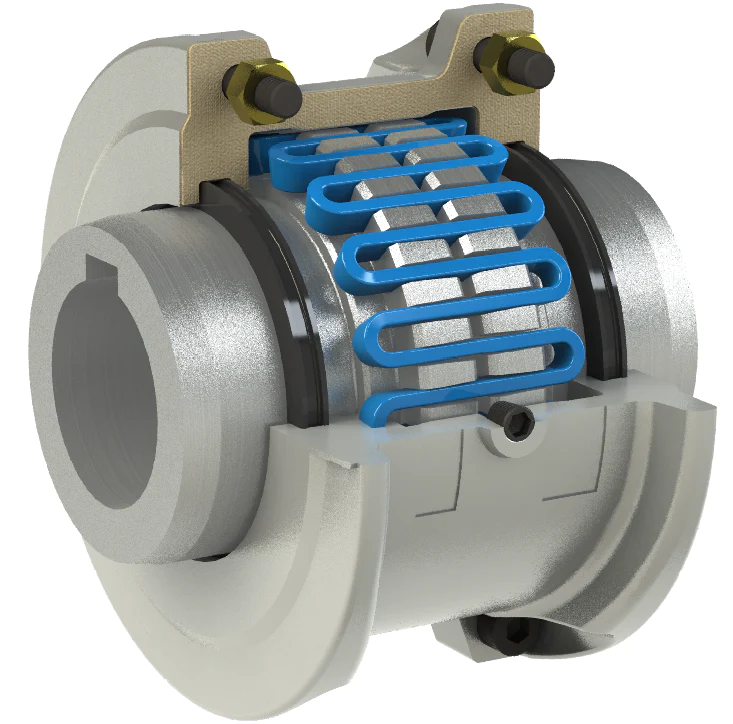

- Inspect Flexible Elements: For flexible couplings, inspect the flexible elements (e.g., elastomeric inserts or diaphragms) for any damage or defects before installation. Replace damaged elements with new ones as needed.

- Tighten Bolts Gradually: When tightening coupling bolts, follow a gradual tightening sequence in a star or cross pattern to ensure even distribution of the load. This prevents uneven stress on the coupling and shafts.

- Use Locking Devices: Consider using appropriate locking devices, such as split washers, locking nuts, or thread-locking compounds, to prevent bolts from loosening during operation.

- Perform Post-Installation Checks: After installing the coupling, perform post-installation checks to verify proper alignment, bolt tightness, and overall coupling integrity before putting the machinery into full operation.

Following these safety considerations and guidelines is essential to ensure a safe and successful installation of industrial couplings. Regular maintenance and inspections throughout the coupling’s service life are also crucial for identifying potential issues early on and addressing them promptly to prevent accidents or damage to the machinery.

Comparison of Elastomeric Couplings to Metal Couplings in Different Industrial Scenarios

Elastomeric couplings and metal couplings are two common types of couplings used in various industrial scenarios. Each type has its strengths and weaknesses, making them suitable for different applications based on specific requirements. Let’s compare elastomeric couplings to metal couplings in various industrial scenarios:

- Vibration Damping and Misalignment: Elastomeric couplings excel in vibration damping and misalignment compensation. The flexible elastomeric elements of these couplings can absorb and dissipate vibrations, reducing the impact on connected equipment and bearings. They also accommodate angular and parallel misalignments, allowing for smoother operation even in situations where shafts are not perfectly aligned. Metal couplings, especially rigid ones, have limited ability to dampen vibrations and may require precise alignment for optimal performance.

- Torsional Flexibility: Elastomeric couplings offer torsional flexibility, which makes them suitable for applications with shock loads and torque spikes. The elastomeric material acts as a cushion, absorbing sudden shocks and protecting the machinery. Metal couplings, particularly rigid ones, are stiffer and transmit more torsional rigidity, which might not be desirable in scenarios where torsional flexibility is necessary to protect sensitive equipment.

- Corrosive Environments: In corrosive environments, metal couplings made of corrosion-resistant materials, such as stainless steel or specialized alloys, are preferred. They can withstand the effects of chemicals and aggressive substances without degradation. Elastomeric couplings may not be suitable for such environments as the elastomeric materials are generally not as resistant to chemical attack as metals.

- Temperature Extremes: Elastomeric couplings have temperature limitations, and their performance might degrade at very high or low temperatures. In contrast, metal couplings can be designed with materials that offer higher temperature resistance. High-temperature metal couplings are suitable for industries like steel and glass manufacturing, where elevated temperatures are common.

- High Torque Applications: For high-torque applications, metal couplings, especially disc or gear couplings, are preferred due to their higher torque capacity and ability to transmit large amounts of power. Elastomeric couplings may have limitations in high-torque scenarios and are more commonly used in medium to low torque applications.

- Cost and Maintenance: Elastomeric couplings are generally more cost-effective than metal couplings. They have a simpler design and are easier to manufacture. Additionally, elastomeric couplings require less maintenance since they have fewer moving parts and do not need lubrication. On the other hand, metal couplings, especially certain types like gear couplings, may require periodic lubrication and more intricate maintenance procedures.

In summary, the choice between elastomeric couplings and metal couplings depends on the specific requirements of the industrial scenario. Elastomeric couplings are favored in applications where vibration damping, misalignment compensation, and torsional flexibility are essential. They are also cost-effective and require less maintenance. On the other hand, metal couplings are preferred in high-torque applications, corrosive environments, and temperature extremes. They offer higher temperature resistance and torque capacity but may be more complex and require more maintenance.

How to Select the Right Industrial Coupling for Specific Machinery or Equipment?

Selecting the right industrial coupling for specific machinery or equipment involves a careful evaluation of various factors to ensure efficient and reliable power transmission. Here are the key steps to guide you in choosing the appropriate coupling:

- Analyze Torque Requirements:

- Evaluate Speed and Operating Conditions:

- Identify Misalignment:

- Consider Space Constraints:

- Account for Shock and Vibration:

- Check Misalignment Capability:

- Consider Backlash Requirements:

- Review Maintenance and Installation:

- Consult with Coupling Manufacturers:

Determine the torque requirements of the application, including the maximum and continuous torque. This information is crucial in selecting a coupling that can handle the required torque without compromising performance.

Consider the rotational speed and operating conditions of the machinery or equipment. High-speed applications may require couplings that offer precise balance and low vibration. Additionally, assess factors like temperature, ambient conditions, and exposure to chemicals or corrosive agents to choose a coupling material that can withstand the environment.

Assess the potential misalignment between the shafts. Determine whether the machinery is subject to axial, angular, or parallel misalignment during operation. Diaphragm couplings are particularly effective in handling misalignments, making them a suitable choice in such scenarios.

Examine the available space and spatial constraints around the coupling area. Some couplings require more axial space than others, and selecting a compact coupling might be necessary in space-restricted applications.

Understand the magnitude of shock loads and vibrations in the application. Grid couplings and elastomeric couplings, such as jaw couplings, offer excellent shock absorption properties and are ideal for applications with varying loads or high shock forces.

Ensure that the selected coupling can accommodate the expected misalignment without compromising its performance or causing premature wear on the machinery. Disc couplings, for example, are designed for precise alignment applications and may not be suitable for large misalignments.

In applications requiring precision motion, consider the need for low backlash in the coupling. Some couplings, like jaw couplings, may introduce minimal backlash, which can be critical in precise positioning systems.

Assess the ease of installation and maintenance of the selected coupling. Couplings that are easy to install and require minimal maintenance can reduce downtime and improve the overall efficiency of the machinery.

When in doubt, consult with coupling manufacturers or engineering experts. They can provide valuable insights and recommendations based on the specific requirements of your application.

By carefully considering these factors and evaluating the different types of industrial couplings available, you can select the right coupling that best matches the needs of your machinery or equipment. The right coupling choice ensures reliable power transmission, reduces the risk of premature failures, and enhances the overall performance and efficiency of your industrial applications.

editor by CX 2024-03-27