Product Description

| Name | Industrial Grade Stainless Steel Elbow Pipe Fitting Reducer Elbow Lr Elbow for Petroluem |

| Type | LR30,45,60,90,180; SR30,45,60,90,180, customerized |

| Radius type | 1D,1.5D,2.0D,2.5D,3.0D,4.0D,5D,6D,7D, customerized |

| Size | 1/2-48INCH |

| Thickness | 0.5mm-60mm |

| End | bavel end, plain end |

| Grade | SS304, SS316L |

| Standard | ASME B16.9, ASTM A234, ASTM A420, ANSI B16.9, B16.25,B16.28, MSS SP-75 |

| DIN2605, DIN2615,DIN2616,DIN2617 | |

| JIS B2311, B2312, B2313 | |

| EN15713-1, EN15713-2 | |

| GB 12459 | |

| Pressure range | SCH5S,SCH10S,SCH20,SCH30,SCH40,SCH60,SCH80,SCH100,SCH120,SCH140,SCH160,XXS |

| Formed type | Ball forming |

| Raw material technology | Pressed from tube |

| Surface type | Sand blasting, Sand rolling, Acid cleaning |

| Connection type | butt welded |

| Productivity | 20000PCS/MONTH |

| Application | Chemical , power, construction, potroleum, gas, water, steam, |

| Warranty | 1 year |

| Package | cartons, pallet, cases |

| Production period | In 15-60 days CHINAMFG order quantity |

| Payment term | L/C, T/T, WU, etc. |

| Certificate | ISO, PED |

| Closest port for shipment | HangZhou |

| Advantages | 1. Customerized dimensions to meet different requirement 2. quality control from raw materials to the final products 3. Abundant stock 4.Rich export experience 5. Reliable shipping forwarder |

| Ezo stainless steel company was started in 2007. Located in the stainless steel industry zone, HangZhou, China. Ezo stainless steel is the branch company of CHINAMFG valves co.,ltd |

| Totally 145nos of workers and the factory Covers 6800m2. Till now, we have 50 sets of imported and local brand CNC machines ; Plus, we have 2 sets of automatic machining unit. To assure better quality, we have the full inspecting quality control equipment: 2nos Ra roughness instrument, 3nos stainless steel spectrometer, numbers of roundness instrument, numbers of thickness instrument, numbers of radius instrument, 3 nos pressure testing center. |

| Ezo stainless steel provides the following materials: Stainless steel butt welded tube pipe fittings and screwed tube pipe fittings ( butt welded elbow /bend, butt welded tee, butt welded reducers, stub ends, pipe caps,screwed elbows, screwed tee, screwed reducers, hex nipples, couplings Stainless steel flanges(weld neck flange, slip on flange ,blind flange, plate flange ,lap joint flange, socket flange, threaded flange, square flange, marine flange stainless steel filter strainers ( Y filter, inline filter, L filter, housing filter Stainless steel pumps ( stainless steel centrifugal pump, rotary lobe pump, CIP pump,screw pump, emulsion pump) Stainless steel man-ways ( Pressure type man-way, non pressure man-way, round man-way, rectangular man-way Stainless steel tanks ( storage tanks, mixing tanks,emulsion tanks, water tanks |

| Ezo stainless steel services for food, beverage, dairy, chemical, bioth, pharmaceutical, chemical, oil and etc industries. |

| Ezo stainless steel customers are from 80 different countries.After so many years, CHINAMFG knows more about different requirements from different countries’ customers. Ezo stainless steel believes in “What we say, what we do”. We always believe honesty and responsibility is the only way leading to long term business relationship. Trying our best for customers and put ourselves into customers’ shoes. Our commitment ” Never let customers leave us because our poor service”. Making business with us, making friends with us. |

| Product Range | Stainless steel tube pipe fittings Stainless steel flanges stainless steel filter strainers Stainless steel pumps Stainless steel man-ways Stainless steel tanks |

|

| Year Established | 2007 | |

| Factory Size in Square Meters | 6800M2 | |

| NO. OF TOTAL STAFF | 145 | |

| Production Capital | USD | |

| Detail capacity/ MONTH | Butt welded/screw fittings | |

| PUMPS | ||

| Manhole cover | ||

| Tanks | ||

| Investment in Manufacturing Equipment | 750000usd | |

| OUR EQUIPMENTS | 50 nos of CNC Machines | |

| 4 nos of press | ||

| 2 nos of full-automatic CNC center | ||

| 12 nos of plain lathe | ||

| 12 nos of grinding machine | ||

| 3 nos of cutting machine | ||

| 3 nos of chamfering machine | ||

| 40 nos of polishing machine | ||

| 2 nos of hardness test machine | ||

| 3 nos of laser marking machine | ||

| 3 nos of pressure testing machine | ||

| 1 nos of temperature testing machine | ||

| 3 nos of spectro instrument | ||

| 2 nos of surface roughness device | ||

| Primary Competitive Advantages | Strict inspection , honest business way, fast revert on order problem | |

| OEM Services Provided | yes | |

| Design Service Offered | yes | |

| Export Percentage | 80% | |

| MAIN MARKET | USA, Germany, Hungary, Canada, Thailand, Holland, England, South Africa,Indonesia, Saudi, India, New Zealand, Australia, Middle East… | |

| Own Brand Name | EZO | |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

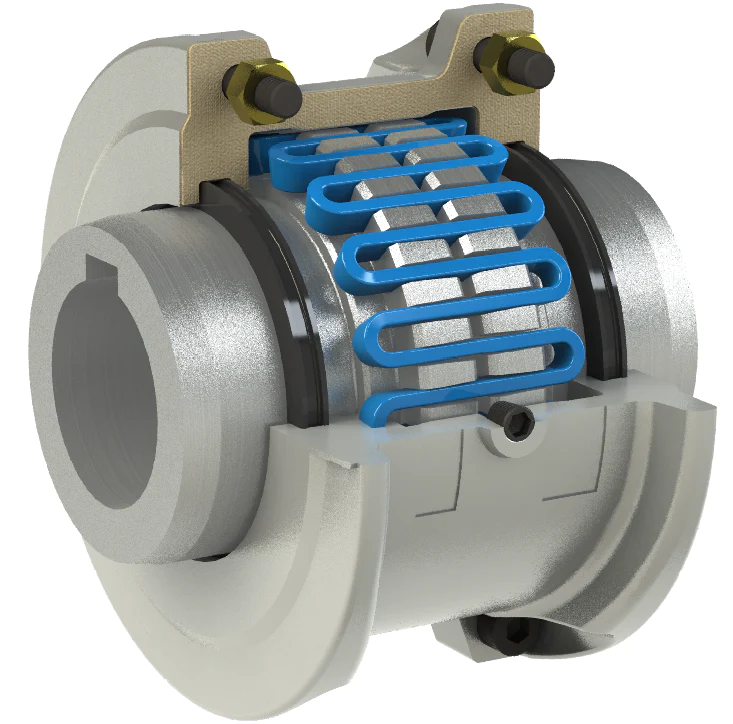

Can Industrial Couplings Accommodate Varying Torque and Speed Requirements in Machinery?

Yes, industrial couplings are designed to accommodate varying torque and speed requirements in machinery. Couplings play a crucial role in transmitting power between connected shafts while allowing for some degree of flexibility and compensation for misalignment. They come in different types and configurations, each tailored to specific applications and operating conditions.

Accommodating Varying Torque Requirements:

Industrial couplings are available in a wide range of sizes and designs, allowing them to handle a broad spectrum of torque capacities. The torque capacity of a coupling depends on factors such as the coupling’s material, size, and construction. For heavy-duty applications with high torque requirements, couplings like gear couplings or grid couplings are suitable choices. On the other hand, elastomeric couplings or diaphragm couplings are commonly used for applications with lower torque demands.

Furthermore, some couplings, such as torque-limiting couplings or overload couplings, are designed to protect machinery from sudden torque spikes or overloads. These couplings disengage temporarily when the torque exceeds a preset limit, preventing damage to the machinery.

Accommodating Varying Speed Requirements:

Industrial couplings can also handle varying speed requirements encountered in different machinery setups. The coupling’s speed capability is influenced by factors such as the material, design, and balancing. For high-speed applications, couplings like flexible disc couplings or metal bellows couplings are commonly used due to their excellent balance characteristics and ability to dampen vibrations at high speeds.

Additionally, some couplings, such as variable-speed couplings, can actively adjust their characteristics to match changing speed requirements. These couplings offer flexibility in power transmission and can optimize efficiency across a wide range of operating speeds.

Customization for Specific Requirements:

Industrial couplings can be customized or selected with specific torque and speed requirements in mind. Manufacturers often provide technical support to engineers and designers to help them choose the most suitable coupling for their applications. By considering factors like operating conditions, load profiles, and the machinery’s torque-speed characteristics, engineers can select or design couplings that precisely match the requirements of the machinery.

In conclusion, industrial couplings are versatile and can accommodate varying torque and speed requirements in machinery. Proper selection and design of the coupling are essential to ensure efficient power transmission, longevity of the machinery, and overall system performance.

Materials Used in Manufacturing Industrial Couplings and Their Impact on Performance

Industrial couplings are manufactured using a variety of materials, each chosen based on its specific properties and the intended application. The choice of material significantly impacts the performance and reliability of the coupling. Here are some commonly used materials and their impact on performance:

- Steel: Steel is a widely used material in manufacturing industrial couplings due to its excellent strength, durability, and resistance to wear and corrosion. Steel couplings are suitable for heavy-duty applications where high torque transmission is required. They are often used in demanding industries such as steel production, mining, and power generation. Steel couplings provide robust performance and are capable of handling harsh operating conditions.

- Cast Iron: Cast iron is another common material for industrial couplings, known for its good mechanical properties and cost-effectiveness. Cast iron couplings are used in various applications, including pumps, compressors, and general machinery. While not as strong as steel, cast iron couplings can still handle substantial torque loads and provide reliable performance in medium-duty applications.

- Stainless Steel: Stainless steel couplings offer excellent corrosion resistance, making them suitable for applications where exposure to moisture, chemicals, or corrosive environments is a concern. Industries such as food processing, pharmaceuticals, and marine often use stainless steel couplings to ensure hygiene, cleanliness, and durability. They are also used in applications where high torsional rigidity and precise alignment are required.

- Aluminum: Aluminum couplings are favored for their lightweight properties and high thermal conductivity. They are commonly used in applications where weight reduction is critical, such as aerospace and automotive industries. However, aluminum has lower strength compared to steel or stainless steel, so aluminum couplings are typically used in low to medium torque applications.

- Elastomers: Elastomeric materials, such as rubber or polyurethane, are used in flexible couplings to provide damping and vibration isolation. Elastomeric couplings can handle misalignment and shock loads while reducing noise and vibration in machinery. They are widely used in applications like pumps, compressors, and conveyor systems to protect both the machinery and surrounding structures from excessive vibrations.

- Composite Materials: Composite materials, which are a combination of different materials, can offer unique advantages in specific applications. For example, fiber-reinforced composites provide a balance between strength and weight, making them suitable for lightweight couplings used in aerospace and high-performance applications.

Choosing the appropriate material for an industrial coupling depends on factors such as the required torque capacity, operating environment, temperature range, and desired service life. In some cases, couplings may be coated or treated to enhance their performance, such as adding surface treatments for improved wear resistance or anti-corrosion properties.

In summary, the selection of materials in manufacturing industrial couplings is critical to ensuring optimal performance and reliability in a wide range of industrial applications. Each material offers specific advantages, and the choice depends on the specific needs of the application and the operating conditions in which the coupling will be used.

Advantages and Disadvantages of Using Flexible Couplings in Industrial Setups

Flexible couplings offer several advantages in industrial setups, but they also come with some disadvantages. Here’s a detailed overview of both aspects:

Advantages:

- Misalignment Compensation: Flexible couplings can compensate for various types of misalignment, including angular, axial, and parallel misalignment. This capability reduces stress on connected machinery, bearings, and shafts, resulting in extended component life and improved reliability.

- Vibration Dampening: Flexible couplings can absorb and dampen vibrations, preventing them from being transmitted to other parts of the machinery or equipment. This feature helps reduce noise and minimizes wear and tear on the system, leading to smoother operation and decreased maintenance requirements.

- Shock Absorption: Some types of flexible couplings, such as grid and elastomeric couplings, offer excellent shock absorption properties. They can handle sudden load changes and impacts, making them suitable for applications with varying loads or in environments prone to shock forces.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing for slight angular displacement between connected shafts. This flexibility helps prevent torsional vibrations and mechanical resonance, improving the overall stability and performance of the machinery.

- Easy Installation and Maintenance: Most flexible couplings are relatively easy to install and require minimal maintenance. They often do not need lubrication, reducing maintenance efforts and downtime, which can result in cost savings.

- Cost-Effective Solution: Flexible couplings are often more cost-effective than rigid couplings, especially in applications where misalignment compensation and shock absorption are required. They offer a balance between performance and affordability.

Disadvantages:

- Backlash: Some flexible couplings introduce a certain amount of backlash or angular play due to their design. In precision applications, this backlash may result in reduced accuracy and positioning errors.

- Lower Torque Capacity: Compared to some rigid couplings, flexible couplings generally have lower torque capacity. In high-torque applications, careful selection is essential to ensure the coupling can handle the required torque without slipping or failing.

- Limitations on High-Speed Applications: Some types of flexible couplings may have limitations in high-speed applications due to factors like balancing requirements or resonance effects.

- Finite Lifespan: Flexible couplings have a finite lifespan and may require periodic replacement, especially in demanding or high-load applications.

When choosing whether to use flexible couplings in an industrial setup, engineers should carefully consider the specific requirements and operating conditions of the application. While flexible couplings offer significant advantages, they may not be suitable for every scenario. Proper selection and regular maintenance of the coupling can ensure optimal performance and extend its lifespan, contributing to the overall efficiency and reliability of the industrial system.

editor by CX 2024-01-19