Product Description

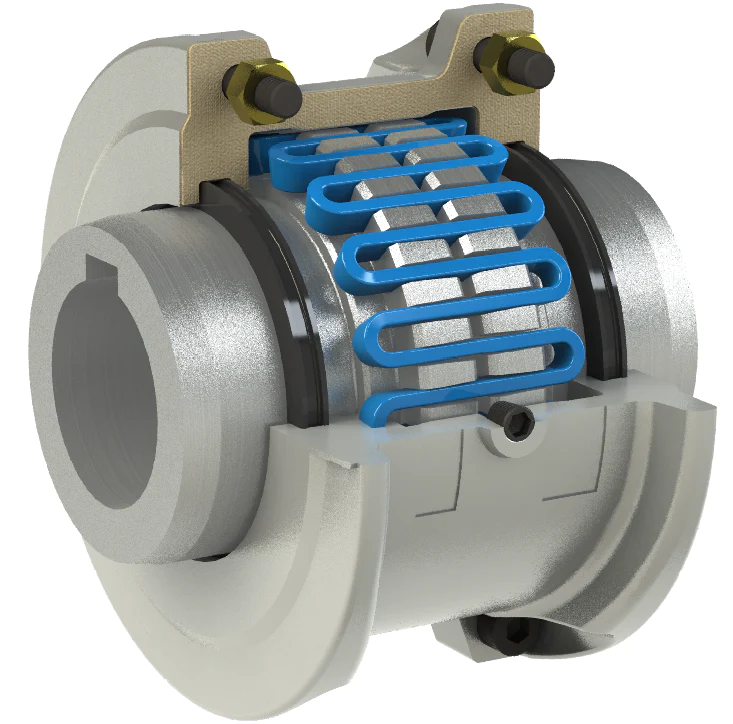

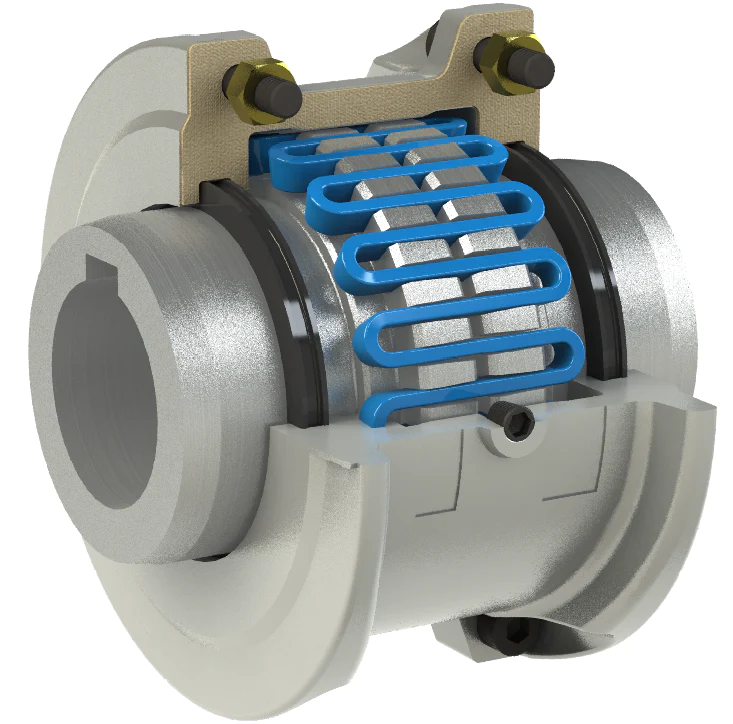

WGP Drum Gear Flexible Coupling With Brake Disc For Heavy Industrial Equipment

Description:

WGP Drum Gear Coupling With Brake Disc has a brake disc, brake disc can rotate speed by controlling the speed to adjust the machine. As shown in figure WGP with brake drum set type gear coupling is divided into I type and II type 2 forms, the only difference is that the brake disc is different.

WGP Drum Gear Coupling With Brake Disc is an improved type of gear coupling, consisting of inner gear and the same number of teeth of the flange half band coupling parts etc..

WGP Drum Gear Coupling With Brake Disc at work, 2 have the relative angular displacement, relative axial sliding periodic internal and external gear tooth surface, will inevitably lead to tooth wear and power consumption, therefore, the gear coupling needs to work in good condition and seal. The toothed coupling has small radial size and large load capacity. It is usually used for shafting transmission under low speed and heavy load conditions. The high accuracy and dynamic balancing gear coupling can be used for high speed transmission.

Features:

1. Double drum-shaped tooth structure, can compensate for a larger axis offset,

2. The brake disc is arranged at the passive end of the coupling, the weight of the brake disc and the working brake load and vibration are completely supported by the half coupling, thereby improving the meshing performance of the drum teeth during braking,

3. The maximum braking torque is not restricted by the structural strength of the coupling, safe and reliable,

4. Compact structure, brake disc cooling conditions are good,

5. Plug-in brake disc can be quickly be replaced without removing the device.

Applications:

Metallurgy, mining, lifting and transportation industries, petroleum, chemical, general machinery and other heavy machinery shaft drive.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Signs of Wear and Failure in Industrial Couplings, and How to Address Them

Industrial couplings can experience wear and failure over time due to various factors such as misalignment, overloading, fatigue, and lack of maintenance. Recognizing the signs of wear and addressing them promptly is essential to prevent further damage and ensure the safe and efficient operation of machinery. Here are some common signs of wear and failure in industrial couplings and how to address them:

- Excessive Vibrations: Excessive vibrations during operation can indicate misalignment, worn-out flexible elements, or coupling imbalance. Address the root cause of the vibrations by performing alignment checks, inspecting flexible elements, and balancing the coupling if necessary.

- Abnormal Noise: Unusual noises such as clanking, rattling, or grinding sounds may indicate coupling wear or damage. Investigate the source of the noise and inspect the coupling for signs of wear, misalignment, or damaged components. Replace worn or damaged parts as needed.

- High Operating Temperature: An increase in the operating temperature of the coupling could be a sign of excessive friction or inadequate lubrication. Check the coupling’s lubrication level and verify that it is suitable for the operating conditions. Inspect for any signs of rubbing or binding that may generate additional heat.

- Visible Cracks or Damage: Perform regular visual inspections of the coupling for any visible cracks, corrosion, or other damage. If any issues are found, discontinue using the coupling immediately and replace it with a new one to prevent potential catastrophic failure.

- Irregular Shaft Movement: If the shafts connected by the coupling exhibit irregular movement or wobbling during operation, it may indicate coupling wear or misalignment. Conduct alignment checks and inspect the coupling for signs of wear or deformation.

- Loose or Missing Bolts: Loose or missing bolts in the coupling assembly can lead to misalignment and reduced performance. Regularly check and tighten the coupling bolts to the manufacturer’s recommended torque specifications.

- Excessive Backlash: Backlash is the amount of play between the coupling components, which can result from wear or damage to the coupling’s flexible elements. Excessive backlash can affect precision applications. Replace the worn flexible elements or consider upgrading to a coupling with lower backlash.

- Reduced Torque Transmission: A decrease in torque transmission can be an indication of coupling wear or damage. Check for signs of wear on the coupling’s contact surfaces and inspect the flexible elements for deformation or deterioration.

- Unusual Coupling Movement: If the coupling exhibits abnormal movements, such as axial movement or coupling slippage, investigate the cause and address any misalignment or insufficient clamping force in the coupling assembly.

- Frequent Coupling Failures: If the coupling experiences frequent failures, it may indicate improper selection or inadequate maintenance practices. Reevaluate the coupling’s suitability for the application and implement a more rigorous maintenance schedule.

When addressing signs of wear and failure in industrial couplings, it is essential to follow the manufacturer’s guidelines and consult with experienced technicians or engineers if needed. Regular maintenance, timely replacement of worn components, and proper alignment of the coupling can significantly extend its service life and ensure reliable performance in power transmission systems.

Materials Used in Manufacturing Industrial Couplings and Their Impact on Performance

Industrial couplings are manufactured using a variety of materials, each chosen based on its specific properties and the intended application. The choice of material significantly impacts the performance and reliability of the coupling. Here are some commonly used materials and their impact on performance:

- Steel: Steel is a widely used material in manufacturing industrial couplings due to its excellent strength, durability, and resistance to wear and corrosion. Steel couplings are suitable for heavy-duty applications where high torque transmission is required. They are often used in demanding industries such as steel production, mining, and power generation. Steel couplings provide robust performance and are capable of handling harsh operating conditions.

- Cast Iron: Cast iron is another common material for industrial couplings, known for its good mechanical properties and cost-effectiveness. Cast iron couplings are used in various applications, including pumps, compressors, and general machinery. While not as strong as steel, cast iron couplings can still handle substantial torque loads and provide reliable performance in medium-duty applications.

- Stainless Steel: Stainless steel couplings offer excellent corrosion resistance, making them suitable for applications where exposure to moisture, chemicals, or corrosive environments is a concern. Industries such as food processing, pharmaceuticals, and marine often use stainless steel couplings to ensure hygiene, cleanliness, and durability. They are also used in applications where high torsional rigidity and precise alignment are required.

- Aluminum: Aluminum couplings are favored for their lightweight properties and high thermal conductivity. They are commonly used in applications where weight reduction is critical, such as aerospace and automotive industries. However, aluminum has lower strength compared to steel or stainless steel, so aluminum couplings are typically used in low to medium torque applications.

- Elastomers: Elastomeric materials, such as rubber or polyurethane, are used in flexible couplings to provide damping and vibration isolation. Elastomeric couplings can handle misalignment and shock loads while reducing noise and vibration in machinery. They are widely used in applications like pumps, compressors, and conveyor systems to protect both the machinery and surrounding structures from excessive vibrations.

- Composite Materials: Composite materials, which are a combination of different materials, can offer unique advantages in specific applications. For example, fiber-reinforced composites provide a balance between strength and weight, making them suitable for lightweight couplings used in aerospace and high-performance applications.

Choosing the appropriate material for an industrial coupling depends on factors such as the required torque capacity, operating environment, temperature range, and desired service life. In some cases, couplings may be coated or treated to enhance their performance, such as adding surface treatments for improved wear resistance or anti-corrosion properties.

In summary, the selection of materials in manufacturing industrial couplings is critical to ensuring optimal performance and reliability in a wide range of industrial applications. Each material offers specific advantages, and the choice depends on the specific needs of the application and the operating conditions in which the coupling will be used.

How to Select the Right Industrial Coupling for Specific Machinery or Equipment?

Selecting the right industrial coupling for specific machinery or equipment involves a careful evaluation of various factors to ensure efficient and reliable power transmission. Here are the key steps to guide you in choosing the appropriate coupling:

- Analyze Torque Requirements:

- Evaluate Speed and Operating Conditions:

- Identify Misalignment:

- Consider Space Constraints:

- Account for Shock and Vibration:

- Check Misalignment Capability:

- Consider Backlash Requirements:

- Review Maintenance and Installation:

- Consult with Coupling Manufacturers:

Determine the torque requirements of the application, including the maximum and continuous torque. This information is crucial in selecting a coupling that can handle the required torque without compromising performance.

Consider the rotational speed and operating conditions of the machinery or equipment. High-speed applications may require couplings that offer precise balance and low vibration. Additionally, assess factors like temperature, ambient conditions, and exposure to chemicals or corrosive agents to choose a coupling material that can withstand the environment.

Assess the potential misalignment between the shafts. Determine whether the machinery is subject to axial, angular, or parallel misalignment during operation. Diaphragm couplings are particularly effective in handling misalignments, making them a suitable choice in such scenarios.

Examine the available space and spatial constraints around the coupling area. Some couplings require more axial space than others, and selecting a compact coupling might be necessary in space-restricted applications.

Understand the magnitude of shock loads and vibrations in the application. Grid couplings and elastomeric couplings, such as jaw couplings, offer excellent shock absorption properties and are ideal for applications with varying loads or high shock forces.

Ensure that the selected coupling can accommodate the expected misalignment without compromising its performance or causing premature wear on the machinery. Disc couplings, for example, are designed for precise alignment applications and may not be suitable for large misalignments.

In applications requiring precision motion, consider the need for low backlash in the coupling. Some couplings, like jaw couplings, may introduce minimal backlash, which can be critical in precise positioning systems.

Assess the ease of installation and maintenance of the selected coupling. Couplings that are easy to install and require minimal maintenance can reduce downtime and improve the overall efficiency of the machinery.

When in doubt, consult with coupling manufacturers or engineering experts. They can provide valuable insights and recommendations based on the specific requirements of your application.

By carefully considering these factors and evaluating the different types of industrial couplings available, you can select the right coupling that best matches the needs of your machinery or equipment. The right coupling choice ensures reliable power transmission, reduces the risk of premature failures, and enhances the overall performance and efficiency of your industrial applications.

editor by CX 2024-03-07