Product Description

Product Description

Product Parameters

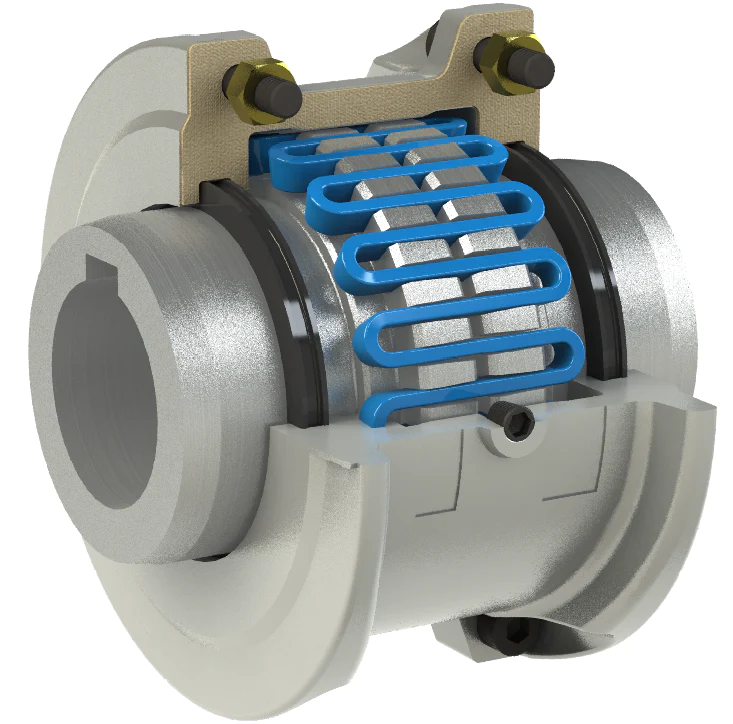

| product | Wd Type Cross Shaft Universal Coupling for Industrial Vehicle |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| kind | expansion sleeve Z1/Z2/Z3/Z4/Z5/Z6/Z7/Z8/Z9/Z10/Z11/Z12/Z13/Z14/Z18/Z19 |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Common Maintenance Practices for Industrial Couplings to Ensure Optimal Performance

Proper maintenance of industrial couplings is essential to ensure their optimal performance and prolong their service life. Regular maintenance practices can help identify potential issues early on, prevent unexpected failures, and maintain the efficiency of power transmission systems. Here are some common maintenance practices for industrial couplings:

- Visual Inspection: Perform regular visual inspections of the couplings to check for any signs of wear, damage, or misalignment. Look for cracks, corrosion, or excessive vibration marks that may indicate a problem.

- Lubrication: Some types of couplings require lubrication for smooth operation. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication. Regularly check and replenish the lubricant as needed.

- Bolt Tightening: Check the tightness of coupling bolts and fasteners periodically. Loose bolts can lead to misalignment and reduced coupling performance. Ensure that the bolts are properly torqued to the manufacturer’s specifications.

- Alignment Check: Regularly inspect and assess the alignment of the connected shafts. Misalignment can lead to premature wear and failure of the coupling. Realign the shafts if necessary to maintain proper coupling operation.

- Balance Check: In high-speed applications, ensure that the coupling is properly balanced to avoid excessive vibrations and potential damage to the machinery. Imbalanced couplings can lead to increased stress on bearings and other components.

- Temperature Monitoring: Monitor the operating temperature of the coupling during normal operation. Drastic temperature increases may indicate issues with lubrication or misalignment. Address any temperature abnormalities promptly.

- Inspect Flexible Elements: For flexible couplings, inspect the flexible elements, such as elastomeric inserts or diaphragms, for signs of wear or deterioration. Replace worn or damaged elements to maintain the coupling’s performance.

- Regular Maintenance Schedule: Establish a regular maintenance schedule for the industrial couplings based on the manufacturer’s recommendations and the specific operating conditions of the machinery. Stick to the schedule to prevent potential problems and ensure the couplings are always in optimal condition.

- Keep the Environment Clean: Maintain a clean environment around the couplings to prevent the accumulation of dirt, debris, or contaminants that can interfere with their operation.

- Training and Education: Ensure that personnel responsible for coupling maintenance receive proper training and education on best practices. Knowledgeable maintenance staff can perform inspections more effectively and identify potential issues proactively.

By implementing these common maintenance practices, industrial facilities can maximize the performance and longevity of their couplings, minimize downtime, and avoid costly repairs or replacements. Regular maintenance not only ensures optimal coupling operation but also contributes to the overall efficiency and reliability of power transmission systems in industrial applications.

Materials Used in Manufacturing Industrial Couplings and Their Impact on Performance

Industrial couplings are manufactured using a variety of materials, each chosen based on its specific properties and the intended application. The choice of material significantly impacts the performance and reliability of the coupling. Here are some commonly used materials and their impact on performance:

- Steel: Steel is a widely used material in manufacturing industrial couplings due to its excellent strength, durability, and resistance to wear and corrosion. Steel couplings are suitable for heavy-duty applications where high torque transmission is required. They are often used in demanding industries such as steel production, mining, and power generation. Steel couplings provide robust performance and are capable of handling harsh operating conditions.

- Cast Iron: Cast iron is another common material for industrial couplings, known for its good mechanical properties and cost-effectiveness. Cast iron couplings are used in various applications, including pumps, compressors, and general machinery. While not as strong as steel, cast iron couplings can still handle substantial torque loads and provide reliable performance in medium-duty applications.

- Stainless Steel: Stainless steel couplings offer excellent corrosion resistance, making them suitable for applications where exposure to moisture, chemicals, or corrosive environments is a concern. Industries such as food processing, pharmaceuticals, and marine often use stainless steel couplings to ensure hygiene, cleanliness, and durability. They are also used in applications where high torsional rigidity and precise alignment are required.

- Aluminum: Aluminum couplings are favored for their lightweight properties and high thermal conductivity. They are commonly used in applications where weight reduction is critical, such as aerospace and automotive industries. However, aluminum has lower strength compared to steel or stainless steel, so aluminum couplings are typically used in low to medium torque applications.

- Elastomers: Elastomeric materials, such as rubber or polyurethane, are used in flexible couplings to provide damping and vibration isolation. Elastomeric couplings can handle misalignment and shock loads while reducing noise and vibration in machinery. They are widely used in applications like pumps, compressors, and conveyor systems to protect both the machinery and surrounding structures from excessive vibrations.

- Composite Materials: Composite materials, which are a combination of different materials, can offer unique advantages in specific applications. For example, fiber-reinforced composites provide a balance between strength and weight, making them suitable for lightweight couplings used in aerospace and high-performance applications.

Choosing the appropriate material for an industrial coupling depends on factors such as the required torque capacity, operating environment, temperature range, and desired service life. In some cases, couplings may be coated or treated to enhance their performance, such as adding surface treatments for improved wear resistance or anti-corrosion properties.

In summary, the selection of materials in manufacturing industrial couplings is critical to ensuring optimal performance and reliability in a wide range of industrial applications. Each material offers specific advantages, and the choice depends on the specific needs of the application and the operating conditions in which the coupling will be used.

Primary Functions of Industrial Couplings in Power Transmission Systems

Industrial couplings play a crucial role in power transmission systems, enabling the efficient transfer of torque between rotating shafts. These couplings serve several primary functions that are essential for the smooth and reliable operation of machinery and equipment. Here are the key functions of industrial couplings:

- Torque Transmission: One of the primary functions of industrial couplings is to transmit torque from one shaft to another. When connected, the coupling allows the torque generated by the driving shaft to be transferred to the driven shaft, facilitating rotational motion in the machinery.

- Misalignment Compensation: Industrial couplings are designed to accommodate misalignments between connected shafts. Misalignments can occur due to various factors such as manufacturing tolerances, thermal expansion, and operational loads. Flexible couplings, such as diaphragm couplings and elastomeric couplings, can handle misalignments and prevent excessive stress and wear on the machinery caused by misaligned shafts.

- Vibration Dampening: Vibrations generated during operation can cause wear and fatigue on machinery components. Industrial couplings, especially flexible couplings, have the ability to dampen vibrations and prevent them from propagating through the entire system. By reducing vibrations, the couplings contribute to a quieter and more stable operation.

- Shock Absorption: In applications where sudden load changes or impacts can occur, industrial couplings with shock-absorbing capabilities are essential. Grid couplings and elastomeric couplings are examples of couplings that can absorb and cushion shocks, protecting the machinery from damage and improving its longevity.

- Torsional Flexibility: Industrial couplings provide torsional flexibility, allowing for slight angular displacement between the shafts. This flexibility is vital in systems where there are variations in the angular position of the shafts or where torsional vibrations need to be minimized.

- Compensation for Thermal Expansion: During operation, machinery components can experience temperature variations, leading to thermal expansion or contraction. Industrial couplings can compensate for the resulting changes in shaft length, ensuring the system maintains proper alignment and performance even under fluctuating temperature conditions.

- Connecting Disparate Components: In complex industrial setups, couplings are used to connect disparate components, such as motors, gearboxes, and pumps, allowing them to work together as an integrated system. The coupling acts as a mechanical bridge, enabling the transmission of power between the various components.

Overall, industrial couplings are critical components in power transmission systems, enhancing the performance, reliability, and longevity of machinery and equipment. Their ability to handle misalignments, dampen vibrations, absorb shocks, and provide torsional flexibility ensures that power is transmitted smoothly and efficiently, ultimately contributing to the seamless operation of industrial processes and applications.

editor by CX 2024-05-10