Product Description

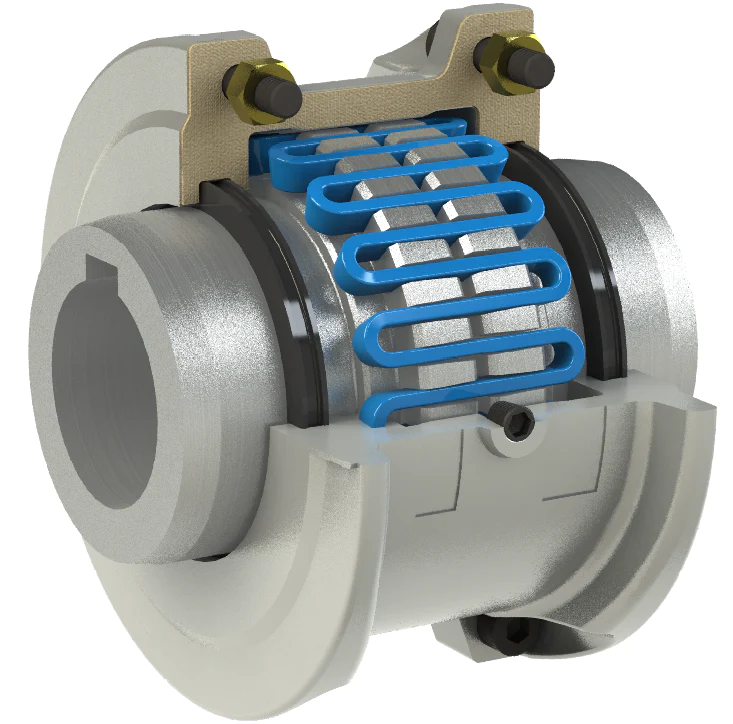

LZD Type Tapered Shaft Hole Elastic Coupling(GB/T 5015-2003)

♦Description

♦Basic Parameter and Main Dimension

Allowable Compensation for Elastic Pin&Bush Gear Couplings

Note: N.m= Nominal Torque; r/min= Allowable speed of rotation; d1.d2= Diameter of shaft hole;

Y L= Length of shaft hole; kg.m²= Rotational inertia; kg= Mass

△Y= Radial; △X= Axial; △α= Angular

1. The measuring part of radial compensation is half of the maximum outer circle width of the half coupling.

2. The compensation quantity listed in the table refers to the relative offset of 2 axes caused by installation error, shock, vibration, deformation, temperature change and other factors. The installation error must be less than the value listed in the table.

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

♦Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2: Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3: How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstance.

Q 6: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 7: Do you have inspection procedures for coupling?

A: 100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Q 9: What’s your payment?

A: T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Examples of Successful Industrial Coupling Applications

Industrial couplings are essential components in various machinery and equipment across different industries. Their versatility, reliability, and ability to handle diverse operating conditions have led to numerous successful applications. Here are some real-world examples of successful industrial coupling applications:

- Pumps and Compressors: In the oil and gas industry, centrifugal pumps and compressors are used for fluid transportation and compression. Gear couplings are commonly employed in these applications due to their high torque capacity and ability to handle misalignment caused by thermal expansion. They ensure reliable power transmission and efficient operation of critical equipment in harsh environments.

- Steel Industry: The steel manufacturing process involves heavy machinery subjected to high torque and intermittent loads. Grid couplings are extensively used in steel rolling mills to connect the motors and rolling stands. Their torsional flexibility helps dampen shocks and vibrations during the rolling process, ensuring precision and reducing wear on the equipment.

- Pulp and Paper Processing: In the pulp and paper industry, large rotary drums and rolls require smooth and reliable power transmission. Disc couplings are commonly used in these applications due to their ability to handle misalignment and high speeds. They ensure precise control during paper manufacturing processes, resulting in consistent product quality.

- Power Generation: Power plants rely on large turbines, generators, and compressors that require efficient power transmission. Diaphragm couplings are well-suited for such high-power applications due to their torsional stiffness and ability to handle misalignment. They provide smooth torque transmission and help maintain precise alignment, enhancing the overall efficiency of power generation systems.

- Automotive Industry: The automotive industry utilizes various types of couplings for different applications. Universal joints are commonly used in drive shafts, enabling power transmission between the engine and wheels while allowing for movement due to suspension and steering. Additionally, elastomeric couplings are employed in engine-driven accessories, such as water pumps and power steering systems, to reduce vibrations and noise.

- Marine Propulsion: In marine applications, where space and weight are critical considerations, flexible couplings play a vital role in connecting the engine to the propeller shaft. These couplings accommodate misalignment caused by hull deflection and vibration, ensuring smooth and efficient propulsion while reducing stress on the drivetrain.

- Mining Equipment: Mining operations involve heavy-duty machinery operating in challenging conditions. Fluid couplings are commonly used in conveyors, crushers, and draglines to start and control the speed of large motors while providing overload protection. These couplings protect the machinery from excessive starting torque and shock loads, enhancing their longevity and reducing downtime.

These examples illustrate the widespread use and success of industrial couplings across diverse industries. The careful selection of the appropriate coupling type for each application ensures reliable power transmission, reduced downtime, and improved overall system performance.

Where to Find Reliable Suppliers or Manufacturers of Industrial Couplings for Your Specific Needs

When looking for reliable suppliers or manufacturers of industrial couplings for your specific needs, there are several avenues you can explore:

- Online Industrial Directories: Online industrial directories are a valuable resource to find suppliers and manufacturers of industrial couplings. Websites like Thomasnet, Alibaba, and GlobalSpec allow you to search for specific types of couplings and filter results based on your requirements, location, and other parameters.

- Trade Shows and Exhibitions: Attend industry-specific trade shows and exhibitions related to mechanical engineering, power transmission, or the specific industry you are involved in. These events often feature a wide range of suppliers and manufacturers showcasing their products, including industrial couplings. It gives you an opportunity to interact directly with the companies and evaluate their offerings.

- Industry Associations: Many industries have trade associations or organizations that provide resources and support to their members. These associations often maintain directories or lists of approved suppliers and manufacturers. Contacting the relevant association can help you find trustworthy sources for industrial couplings.

- Referrals and Recommendations: Seek recommendations from colleagues, industry peers, or other professionals who have experience with industrial couplings. Referrals from trusted sources can provide valuable insights into the reliability and quality of specific suppliers or manufacturers.

- Online Research: Perform in-depth online research using search engines to find companies that specialize in manufacturing industrial couplings. Check their websites for product catalogs, certifications, and customer reviews to assess their capabilities and reputation.

- Supplier Evaluation: Once you have identified potential suppliers or manufacturers, evaluate them based on factors such as their product range, manufacturing capabilities, quality control measures, certifications, lead times, and customer service. Request samples or product specifications to ensure they meet your specific needs.

Remember to conduct due diligence and verify the credentials of the suppliers or manufacturers before making any commitments. Look for companies with a proven track record, relevant certifications (e.g., ISO 9001), and a strong commitment to customer satisfaction. Additionally, consider the location and shipping options to ensure timely delivery of the industrial couplings to your facility.

By exploring these avenues and making informed decisions, you can find reliable suppliers or manufacturers that provide high-quality industrial couplings tailored to your specific needs and industry requirements.

How to Select the Right Industrial Coupling for Specific Machinery or Equipment?

Selecting the right industrial coupling for specific machinery or equipment involves a careful evaluation of various factors to ensure efficient and reliable power transmission. Here are the key steps to guide you in choosing the appropriate coupling:

- Analyze Torque Requirements:

- Evaluate Speed and Operating Conditions:

- Identify Misalignment:

- Consider Space Constraints:

- Account for Shock and Vibration:

- Check Misalignment Capability:

- Consider Backlash Requirements:

- Review Maintenance and Installation:

- Consult with Coupling Manufacturers:

Determine the torque requirements of the application, including the maximum and continuous torque. This information is crucial in selecting a coupling that can handle the required torque without compromising performance.

Consider the rotational speed and operating conditions of the machinery or equipment. High-speed applications may require couplings that offer precise balance and low vibration. Additionally, assess factors like temperature, ambient conditions, and exposure to chemicals or corrosive agents to choose a coupling material that can withstand the environment.

Assess the potential misalignment between the shafts. Determine whether the machinery is subject to axial, angular, or parallel misalignment during operation. Diaphragm couplings are particularly effective in handling misalignments, making them a suitable choice in such scenarios.

Examine the available space and spatial constraints around the coupling area. Some couplings require more axial space than others, and selecting a compact coupling might be necessary in space-restricted applications.

Understand the magnitude of shock loads and vibrations in the application. Grid couplings and elastomeric couplings, such as jaw couplings, offer excellent shock absorption properties and are ideal for applications with varying loads or high shock forces.

Ensure that the selected coupling can accommodate the expected misalignment without compromising its performance or causing premature wear on the machinery. Disc couplings, for example, are designed for precise alignment applications and may not be suitable for large misalignments.

In applications requiring precision motion, consider the need for low backlash in the coupling. Some couplings, like jaw couplings, may introduce minimal backlash, which can be critical in precise positioning systems.

Assess the ease of installation and maintenance of the selected coupling. Couplings that are easy to install and require minimal maintenance can reduce downtime and improve the overall efficiency of the machinery.

When in doubt, consult with coupling manufacturers or engineering experts. They can provide valuable insights and recommendations based on the specific requirements of your application.

By carefully considering these factors and evaluating the different types of industrial couplings available, you can select the right coupling that best matches the needs of your machinery or equipment. The right coupling choice ensures reliable power transmission, reduces the risk of premature failures, and enhances the overall performance and efficiency of your industrial applications.

editor by CX 2024-04-25